Description

Ion exchange is used in water treatment, including water softening, industrial demineralization, condensate polishing, ultrapure water production, and wastewater treatment. It can also provide a method of separation in many non-water processes, such as desiccation and chromatographic separation. It has special utility in chemical synthesis, manufacturing, food processing, mining, power generation, agriculture, and a variety of applications and other industries.

Solids can be separated from liquid media by means of filtration, soluble substances require something different. Ion exchange is the reversible interchange of ions between a solution with soluble ionized substances and a solid (the ion exchange material), in which there is no permanent change in the structure of the solid.

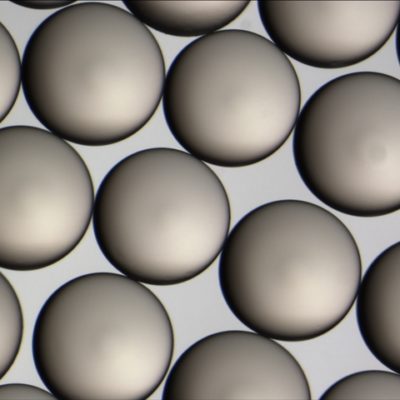

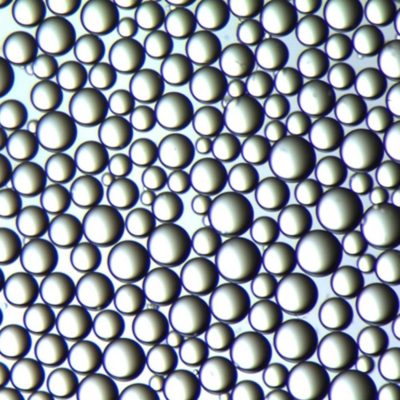

Fundamentally, the ion exchange process is this: A solution passes through or over ion exchange resins, which contain mobile or exchangeable ions. The solute ions that have a stronger affinity to the resins than the ions on the resins are removed from the solution and are replaced by the exchangeable ions on the resins. In water processing, ion exchange typically removes hardness in softening applications and all dissolved ions in demineralization. Ion exchange is also used to remove nitrate, chromate, arsenic, and other specific contaminants from drinking water.

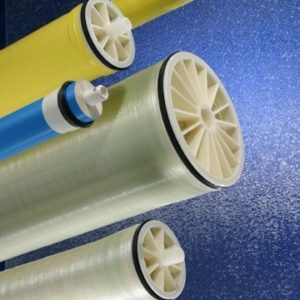

Ion exchange processes can be conducted in continuous or batch mode, with most water treatment IX processes run in a continuous mode. Continuous ion exchange processes take place in a column or vessel containing a deep bed of ion exchange resin beads; water typically flows down through the resin bed. When resin capacity becomes exhausted, the resins are regenerated.

Source: Courtesy of DuPont™ Water Solutions